Product Description

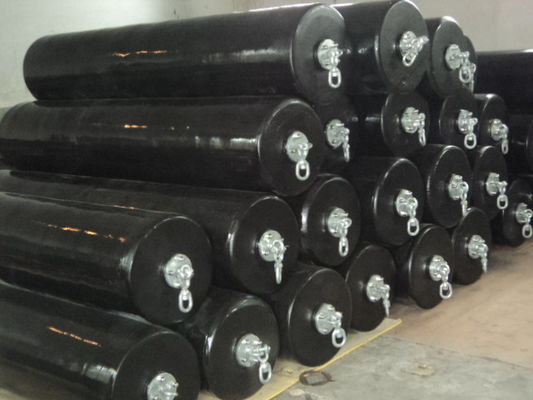

Cylindrical foam filled fender/foam filled marine fenders/ large boat fenders/foam filled fender/custom boat fenders

1. Company introduction

In general, for ship-to-ship operation of light ships, two points of contact are sufficient. However, for the operation of large ships by ship, an additional 1-2 fenders of the same specification must be used to ensure safety. Inflatable rubber fenders can be used as the main protection system to absorb the energy of the ship to the ship, while keeping the two ships at a certain distance. In addition, a small inflatable rubber fender can also be hung on the side of the ship as a secondary protection. Inflatable rubber fenders require chains and rope links to be hung from the ship or dock, and their specifications are selected according to the size of the fender and the environment in which it is used.

♦ Company mainly produces and sells inflatable rubber fenders, EVA polyurethane fenders and marine airbags, and the products are unique formula and advanced production technology.

♦ Company products has passed ISO9001:2000, CCS, DNV, LR ,etc.

♦ Company products are exported to USA, France, Italy, UK, Singapore, Indonesia, Korea and other countries and regions.

2. EVA Polyurethane Foam Filled Floating Fender Technical Parameter Table

| Model |

D

(mm)

|

L

(mm)

|

Compression 60% |

Reference Weight(kg) |

| Counter-force(KN) |

Energy Absorption

(KJ)

|

| Ø 500×1000L |

500 |

1000 |

71 |

8 |

34 |

| Ø 600×1000L |

600 |

1000 |

86 |

12 |

45 |

| Ø 700×1500L |

700 |

1500 |

161 |

27 |

101 |

| Ø 1000×1500L |

1000 |

1500 |

205 |

49 |

206 |

| Ø 1000×2000L |

1000 |

2000 |

274 |

64 |

275 |

| Ø 1200×2000L |

1200 |

2000 |

337 |

93 |

405 |

| Ø 1200×2400L |

1200 |

2400 |

390 |

110 |

475 |

| Ø 1350×2500L |

1350 |

2500 |

463 |

145 |

626 |

| Ø 1500×3000L |

1500 |

3000 |

624 |

216 |

927 |

| Ø 1700×3000L |

1700 |

3000 |

696 |

273 |

1191 |

| Ø 2000×3500L |

2000 |

3500 |

990 |

456 |

1923 |

| Ø 2000×4000L |

2000 |

4000 |

1110 |

505 |

2298 |

| Ø 2200×4500L |

2200 |

4500 |

1396 |

679 |

2992 |

| Ø 2500×4000L |

2500 |

4000 |

1386 |

781 |

3434 |

| Ø 2500×5000L |

2500 |

5000 |

1750 |

985 |

4272 |

| Ø 3000×5000L |

3000 |

5000 |

2050 |

1410 |

6411 |

| Ø 3000×6000L |

3000 |

6000 |

2460 |

1695 |

7293 |

| Ø 3300×6500L |

3300 |

6500 |

2950 |

2245 |

8335 |

| Ø 4500×9000L |

4500 |

9000 |

19650 |

7860 |

21460 |

| Model |

D

(mm)

|

L

(mm)

|

Compressible 60% |

Weight

(kg)

|

| |

|

|

Counter-force

(KN)

|

Energy Absorption

(KJ)

|

|

| Ø 500×1000L |

500 |

1000 |

71 |

8 |

34 |

| Ø 600×1000L |

600 |

1000 |

86 |

12 |

45 |

| Ø 700×1500L |

700 |

1500 |

161 |

27 |

101 |

| Ø 1000×1500L |

1000 |

1500 |

205 |

49 |

206 |

| Ø 1000×2000L |

1000 |

2000 |

274 |

64 |

275 |

| Ø 1200×2000L |

1200 |

2000 |

337 |

93 |

405 |

| Ø 1200×2400L |

1200 |

2400 |

390 |

110 |

475 |

| Ø 1350×2500L |

1350 |

2500 |

463 |

145 |

626 |

| Ø 1500×3000L |

1500 |

3000 |

624 |

216 |

927 |

| Ø 1700×3000L |

1700 |

3000 |

696 |

273 |

1191 |

| Ø 2000×3500L |

2000 |

3500 |

990 |

456 |

1923 |

| Ø 2000×4000L |

2000 |

4000 |

1110 |

505 |

2298 |

| Ø 2200×4500L |

2200 |

4500 |

1396 |

679 |

2992 |

| Ø 2500×4000L |

2500 |

4000 |

1386 |

781 |

3434 |

| Ø 2500×5000L |

2500 |

5000 |

1750 |

985 |

4272 |

| Ø 3000×5000L |

3000 |

5000 |

2050 |

1410 |

6411 |

| Ø 3000×6000L |

3000 |

6000 |

2460 |

1695 |

7293 |

| Ø 3300×6500L |

3300 |

6500 |

2950 |

2245 |

8335 |

| Ø 4500×9000L |

4500 |

9000 |

19650 |

7860 |

21460 |

3. Product Introduction

The EVA foam filled fender uses polyurethane elastomer and as the buffer medium, which makes the ship have better anti-collision effect when it is near the ship or dock.

Polyurethane elastomer is a new kind synthetic polymer whose performance has both advantages of plastic and rubber. The high strength of plastic and good elasticity of rubber

Henger polyurethane Eva foam filled fender made of high quality high density Evafoam and new formulations to coating polyurea ,so the eva foam filled fender is have beautiful colors and very durable.

- Inner:We use high density closed cell eva foam, do not absorb water and have big buoyancy

- Outer:We coating high quality polyurea elastomer outside , the surface is bright andcleanand have certain elasticity

- At both ends: For small polyurethane eva foam fender can use rope hanging on both sides. For Large eva foam fender will use rings or flange for connection.

- Shape: we can make customer size, shape and color;also can make rope net or tyre-chain net outside to protect the fender body.

- Long life span

Qualified products delivery after testing

Polyurethane foam filled fender is made of high elastic modulus of new polymerization materials, which has high strength, high elasticity, high adhesion force and the maximum anti-seepage, anti-aging features etc. Polyurethane foam filled fender is mainly choose the closed-cell foam materials as buffered medium to reduce the damage of collision. Currently, Polyurethane foam filled fender produced by HENGER is used very widely in the world, include the port, coastal and ship by ship operation.Polyurethane foam filled fender as a substitute of Pneumatic Rubber fender, which adopting the new coating formular so that the product become more gorgeous and solid. Compared with Pneumatic Rubber Fender, it can using longer time and easy to install in the practices. Polyurethane foam filled fender choose the polyurea material for outer layer and internal using polyurethane foam materials or plastic foam as the cushion medium. It is using compression deformation to absorb the impact energy of the vessels, so that it can help the ship or wharf to reduce the collision damage.

4. Floating foam filled marine polyurethane EVA fender

EVA foam filled fender is a kind of constructive fender with polyurethane materials as its outer protective layer and polyethylene or plastic foam core forming the resilient inner part. Through comoressive deformation to absorb impacting energy of the ship when using. So that it can reduce destructive effect to the pier and the ship.

Polyurethane floating fender is also a kind of compressed fender which builds outer protecive layer with polyurethanmaterials and adopts polyurethane foaming material or plastic foaming as buffer medium ;the destructive effects on docks and ships will be reduced by thecompression to absorb the impact energy from ships in the course of using polyurethane floating fender .

Foam filled marine fenders absorbs the impacts whilst the skin resists wear and tear in any tough conditions, thus providing tough, heavy-duty marine fendering systems for harbors, offshore and ship-to-ship applications.

5. Why Choose Us

A. Short Delivery Time If Clients Need Urgently

B. As we have Mature and Professional Sales Team

C. Certified by the high quality products

D.A variety of specifications optional, match for a variety of clients

E.Competitive price, high cost performance products

6. What is EVA foam filled fender(buoy)?

A)Eva foam filled fender is a kind of compression type fender.It use high density Eva foam as buffer and coating polyurea elastomer materials outside as a protective layer. It can absorb the impact energy created by the moving vessel by its compression deformation. In order to reduce damage to the wharf and ship.

B)Eva foam filled fender have good floating performance, will not influenced by tidal range;The polyurea elastomer have many Bright colors, can coating the color as customer request. Compared with pneumatic rubber fender, don't need to inflatable and very safe when using , also do not need to maintain.

1.Colorful

2.unsinkable design

3.Can as float rod on the sea

4.Flexible,cost-saving

5.Remains fully functional even if skin is punctured

6.Easy to install,move and use. Low maintenance.

Foam filled fenders are high performance and heavy-duty floating fender system. Foam fender is made of polyurethane elastomer skin( or rubber skin), nylon reinforcement layer and closed-cell resilient foam. It has high energy absorption and low reaction force.

EVA Foam filled fender is filled with high density foam. Nowadays, they are widely used in docks, ships, boats and vessels. High energy-absorption, corrosion resistance as well as anti-tearing. They can protect the docks and all the ships well when stopped.Since 1981, Qingdao Henger Factory began to study the foam filled fender and introduce advanced technique and equipment. Superior quality and competitive price ensure our good reputation in the international market.

7. EVA Polyurethane Foam Filled Floating Fender Product Feature

Henger Invented new foam fender manufacturing method with blind hole hydrophobic foam as core and polyurea as outer coating, which has following features:

Good Hydrophobicity

The core material of Henger foam filled fender is bind hole hydrophobic foam with light weight and good energy absorption capability. It wont absorb water even cracking

High Performance of Outer Coating Layer

The polyurea protective coating has very good performance of anti collision, anti friction, compression resistance, oil proof, water proof and weather fastness.

Fast and Easy Installation

The fender is made with flange and swivel for fast installation, customer could install it very fast without any professional guidance from experts.

Multiple Color Options

The appearance color could be customized in any colors appointed by customer with provided PANTONE.

Multiple Form & Size Options

The fender is made of high plasticity foam, whose appearance form and dimensional size are highly customizable.various colors, forms & sizes for option

8. EVA Polyurethane Foam Filled Floating Fender Application

- Harbors, ships

- gravity wharf and dolphin type quay, especially for wharves with bigger

- tidal range

- STS, STD operation

- Protective fender for bridge pier

- Protecting fender for special military fleet or submarine

- Applied together with other forms of fender like pneumatic rubber fender, hydro pneumatic fender, etc.

9. FAQ

1. What’s the material of your airbags and pneumatic rubber fender?

Material: natural rubber+Synthetic-tyre-cord layer for reinforcement

2. What's the advantage of your products?

Pneumatic rubber fender manufactured by mold, It is the sole factory in China that produces mold. Different with hand make products, difference like Vacuum tyre and tube tyre.

3. How long about the shortest delivery time?

We have stock sizes fenders in China now, we can delivery from the nearest warehouse to you.

4. What's your MOQ of rubber airbags and fenders?

MOQ: 1PC Yokohama fender price

5. What's the lifespan of your rubber airbags and pneumatic rubber fender?

Airbags Life span: 6-10 years. Pneumatic rubber fender lifespan more than 10 years.

6. What's the warranty period of your rubber airbags?

12 months. Product will be maintained or returned because of the airbag leakage, take off layers, the head of airbag break off etc,products caused by product quality The repair technology supply for free.

7. What’s your standard of you products?

Airbags manufacture standard strictly with ISO 14409

Pneumatic rubber fender to be satisfy with ISO17357: 2014

8. What kind of certificate can you provide?

DNV.GL, BV CCS LR. certificates are available.