Product Description

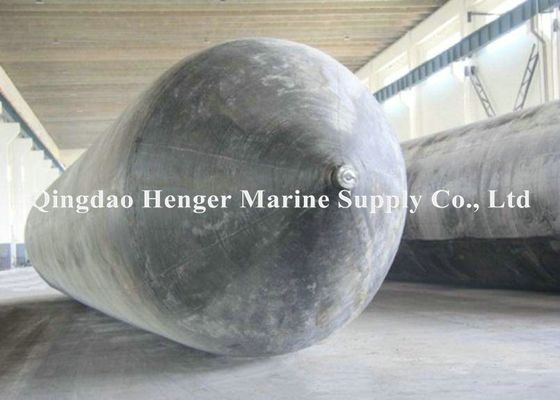

Natural Marine Inflatable Rubber Airbag And Lifting Marine Airbags

Marine Rubber Airbag Introduction

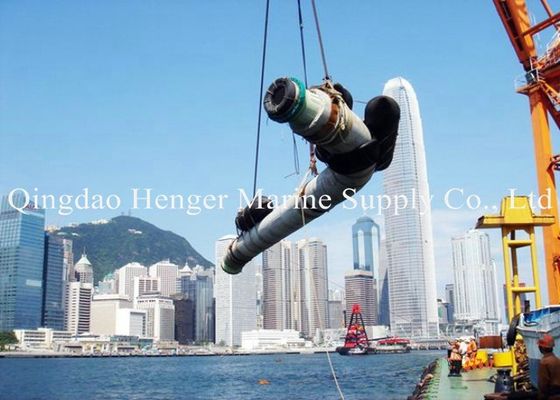

So far, many shipyards have also been using Inflatable Heavy LIfting Airbags to lift heavy objects into the water. These heavy objects are still widely used in daily production and real life.

There are many innovative products with independent intellectual property rights in China. However, in the field of ship launching, marine airbags have a wide range of applications, such as ship launching and upgrading, caisson lifting and moving, heavy lifting, and underwater engineering buoyancy auxiliary equipment. Marine rubber airbags can effectively shorten the construction period and save a lot of money.

Airbag performance

1. Air tightness test

The airbag will be inflated without any load to reach a certain internal test pressure. One hour later, the internal pressure was measured again. Compared with these two data, the pressure loss should be less than 5%.

2. Performance test

When the Inflatable Heavy Lifting Airbag is stationary, inflate the airbag airbag according to customer requirements.

We will carry out strict visual inspection and pore test before shipment. If it is not qualified, it will not be shipped.

3. Blasting test

Since the airbag is a pressure vessel, for safety reasons, before filling the airbag, it must be flushed with water until the airbag ruptures. The water pressure during the airbag sandblasting process should be greater than or equal to the value listed in the standard performance table.

Inflatable Marine Rubber Airbag Technical Parameter:

| Model |

D(m) |

P(Mpa) |

Working Height(m) |

Unit Bearing Capacity(ton/m) |

| 0.4D |

0.5D |

0.6D |

0.4D |

0.5D |

0.6D |

| S1 |

S10

|

0.8 |

0.20 |

0.32 |

0.40 |

0.48 |

15.1 |

12.6 |

10.0 |

| 1 |

0.16 |

0.40 |

0.50 |

0.60 |

15.1 |

12.6 |

10.0 |

| 1.2 |

0.14 |

0.48 |

0.60 |

0.72 |

15.8 |

13.2 |

10.6 |

| 1.5 |

0.11 |

0.60 |

0.75 |

0.90 |

15.5 |

13.0 |

10.4 |

|

S11

|

0.8 |

0.19 |

0.32 |

0.40 |

0.48 |

14.3 |

11.9 |

9.5 |

| 1 |

0.15 |

0.40 |

0.50 |

0.60 |

14.1 |

11.8 |

9.4 |

| 1.2 |

0.13 |

0.48 |

0.60 |

0.72 |

14.7 |

12.2 |

9.8 |

| 1.5 |

0.10 |

0.60 |

0.75 |

0.90 |

14.1 |

11.8 |

9.4 |

|

S12

|

0.8 |

0.24 |

0.32 |

0.40 |

0.48 |

18.1 |

15.1 |

12.1 |

| 1 |

0.19 |

0.40 |

0.50 |

0.60 |

17.9 |

14.9 |

11.9 |

| 1.2 |

0.16 |

0.48 |

0.60 |

0.72 |

18.1 |

15.1 |

12.1 |

| 1.5 |

0.13 |

0.60 |

0.75 |

0.90 |

18.4 |

15.3 |

12.2 |

| 1.8 |

0.10 |

0.72 |

0.90 |

1.08 |

17.0 |

14.1 |

11.3 |

| S2 |

S20

|

1 |

0.24 |

0.40 |

0.50 |

0.60 |

22.6 |

18.8 |

15.1 |

| 1.2 |

0.20 |

0.48 |

0.60 |

0.72 |

22.6 |

18.8 |

15.1 |

| 1.5 |

0.16 |

0.60 |

0.75 |

0.90 |

22.6 |

18.8 |

15.1 |

| 1.8 |

0.13 |

0.72 |

0.90 |

1.08 |

22.0 |

18.4 |

14.7 |

| 2 |

0.12 |

0.80 |

1.00 |

1.20 |

22.6 |

18.8 |

15.1 |

|

S21

|

1 |

0.27 |

0.40 |

0.50 |

0.60 |

25.4 |

21.2 |

17.0 |

| 1.2 |

0.23 |

0.48 |

0.60 |

0.72 |

26.0 |

21.7 |

17.3 |

| 1.5 |

0.18 |

0.60 |

0.75 |

0.90 |

25.4 |

21.2 |

17.0 |

| 1.8 |

0.15 |

0.72 |

0.90 |

1.08 |

25.4 |

21.2 |

17.0 |

| 2 |

0.14 |

0.80 |

1.00 |

1.20 |

26.4 |

22.0 |

17.6 |

|

S22

|

1 |

0.31 |

0.40 |

0.50 |

0.60 |

29.2 |

24.3 |

19.5 |

| 1.2 |

0.26 |

0.48 |

0.60 |

0.72 |

29.4 |

24..5 |

19.6 |

| 1.5 |

0.20 |

0.60 |

0.75 |

0.90 |

28.3 |

23.6 |

18.8 |

| 1.8 |

0.17 |

0.72 |

0.90 |

1.08 |

28.8 |

24.0 |

19.2 |

| 2 |

0.15 |

0.80 |

1.00 |

1.20 |

28.3 |

23.6 |

18.8 |

| 2.5 |

0.12 |

1.00 |

1.25 |

1.50 |

28.3 |

23.6 |

18.8 |

| S3 |

S30

|

1 |

0.35 |

0.40 |

0.50 |

0.60 |

33.0 |

27.5 |

22.0 |

| 1.2 |

0.29 |

0.48 |

0.60 |

0.72 |

32.8 |

27.3 |

21.9 |

| 1.5 |

0.23 |

0.60 |

0.75 |

0.90 |

32.5 |

27.1 |

21.7 |

| 1.8 |

0.19 |

0.72 |

0.90 |

1.08 |

32.2 |

26.8 |

21.5 |

| 2 |

0.17 |

0.80 |

1.00 |

1.20 |

32.0 |

26.7 |

21.4 |

| 2.5 |

0.14 |

1.00 |

1.25 |

1.50 |

33.0 |

27.5 |

22.0

|

Storage of the ship launching airbag

1. When the airbag is not in use, if it needs to be stored for a long time, it should be kept clean and dry. Talc powder should be applied to the surface of the airbag. Place the airbag in a dry and ventilated room and away from the light source. Please place the transportation airbag in a safe place to avoid stretching, compression and deformation.

2. The air bag cannot be close to the heat source.

3. Do not expose the air bag to acids, alkalis, grease and organic solvents.

4. When the airbag boat is not in use, it should be kept flat, not stacked and without heavy objects.

Points to note when using balloons on board:

1. When using Inflatable Heavy LIfting Airbags, control the pressure and prohibit the use of airbags that exceed the working pressure.

During transportation, no sharp or hard objects should touch the airbag to prevent the airbag skin from being pierced. Try to avoid deformation of the airbag length. After inflating the air into the water, avoid inflating the air bag.

For example, when the airbag lifts most of the hull, move most of the dock and fill the rolling airbag. If there are still 1-2 piers in compression, then the internal pressure between the airbags should be adjusted so that the ship can be unloaded from the side of the ship. Another example is collisions with other objects due to various reasons in the process of moving the ship. In severe cases, the impacted airbag may be damaged.

If the airbag is not used for a long time, the inflation test should be performed again. The internal air pressure should be the same as the factory test value. During the test, the tester should keep a distance of 3 meters from the airbag. If the airbag is damaged after extensive maintenance, the operating pressure should be reduced

Marine Airbag Specifications:

| Diameter(m) |

1.0 |

1.2 |

1.5 |

1.8 |

2.0 |

Medium Pressure

(4-5) |

Test Pressure |

0.14-0.16 |

0.12-0.14 |

0.10-0.12 |

0.08-0.10 |

0.07-0.09 |

| Working Pressure |

0.12-0.14 |

0.10-0.12 |

0.08-0.10 |

0.07-0.09 |

0.06-0.08 |

High Pressure

(6-8) |

Test Pressure |

0.22-0.26 |

0.20-0.24 |

0.15-0.20 |

0.13-0.16 |

0.12-0.15 |

| Working Pressure |

0.20-0.24 |

0.17-0.22 |

0.13-0.18 |

0.11-0.14 |

0.10-0.13 |

Our Services

Why do customers like to choose us?

1. Value for Money, you will get the best price based on the excellent quality.

2. Unrivalled Expertise, we promise first-rate product quality and service.

3. Good product lifespan and quality warranty, our products has a long servicing life for 10-15years.

4. Professional after-sales service. We will help our customers to solve any product's questions within 24 hours.

5. For our customers, we will provide a set of repaire tools with free.